Time to read: 7 min

Digital Factory Planning & The Digital Factory

- Digital factory planning – welcome to the future!

What is a digital factory and digital factory planning?

In the digital factory of the future, a variety of digital models and tools will be used. In digital factory operations, all data is brought together as part of end-to-end data management – in a digital reality. For example, by simulating various scenarios in a digital image of your real factory (digital twin), you can efficiently plan, evaluate and continuously optimize your manufacturing processes, material flows and production sequences. This optimization process takes place within the framework of digital factory planning.

What are the goals of digital factory planning?

Do you not have a uniform data basis for thorough evaluation? Do you not yet plan your factory processes in a standard way or would you like to improve the productivity of your factory in a holistic way? Not sure how?

Why is digital factory planning so important?

Imagine being able to identify potential sources of error in advance when converting (or building) your production plant and therefore avoiding them. Manufacturing processes, material flows and production sequences can be tested for resilience and functionality by simulating and visualizing different scenarios. Make the most out of this potential.

More and more production companies are faced with the challenge of having to meet individual customer requirements. Digital factory planning enables cost-efficient implementation of batch size 1. Holistic planning and visualization of production processes are the key to success.

Reasons for digital factory planning

Industry 4.0 is on everyone’s mind. Digital factory planning represents an important switch in the direction of Industry 4.0. There are numerous reasons why factories and factory planning should be digitalized:

Webinar

The series assembly of tomorrow – clever production of large products

Reasons for digital factory planning

-

Batch size 1

Increasingly individual and complex products in ever smaller quantities pose new challenges for the manufacturing industry.

-

Collaboration across departments

Complex topics in particular require a lot of time. Good interdepartmental communication and networking is essential to avoid misunderstandings.

-

Cost and time pressure

Due to high cost and time pressure, smooth and flexible workflows are an absolute must.

-

Digitalization pressure

Currently, the effects of digital transformation are being felt in all areas of the value chain.

Approach: 5 steps to a digital factory

-

1. Data management

All data relevant for the planning process from layout planning and production processes are merged.

-

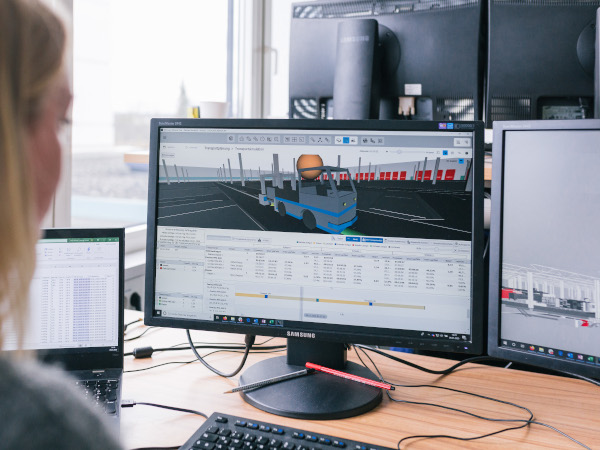

2. Creation of the digital twin

A digital image of the real factory is created.

-

3. First analysis of production processes

The production processes are analyzed in the digital twin and subjected to an initial assessment. Major sources of error are eliminated.

-

4. Simulation of different scenarios

In the digital twin, different scenarios are created, simulated in real time and compared with each other or with the current state. In this way, you improve the planning quality in your production facility.

-

5. Continuous Optimization

All processes, structures and resource usage as well as flows of goods are continuously optimized. This increases productivity and efficiency in factory operations.

What are the benefits of software-supported digital factory planning?

-

Dynamic planning

With software support, you can compare different scenarios and dynamically react to changes.

-

Simple and secure planning

Reduce the complexity of the planning process with data models, simplifying cross-departmental collaboration.

-

3D visualization and simulation

Intelligent software enables you to plan reliably through simulation and 3D visualization. Planning errors are therefore a thing of the past.

-

Everything in one tool

A unified tool brings together different expert areas and eliminates the confusing flood of documents from Excel pivot tables and CAD tools. For better protection with less effort.

Good software can take a lot of work off your hands on the road to digitalization. Curious to learn more? Then see here how you can make your software supported factory a reality.

You have great employees with unique and special skills. The challenge lies in correctly scheduling them over the year and utilizing their abilities most effectively. As a shift planner you must... In many manufacturing companies, final assembly is the stage in the production chain where the greatest value is created for the product. Even the best assemblies and vendor parts are of little... The planning and configuration of industrial racks is an important part of material staging and warehouse planning. Individual rack planning allows for the use of limited space and reduction of...Human Resource Planning Software

Simulation Software for Material Flow

Industrial Rack Planning Software