Logistics Planning with ipolog-Software

Logistics optimization with ipolog – the future of logistics management

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYour logistics planning needs to design systems in such a way that you can master the increasing challenges of the market. An increasing number of varients, smaller quantities and rising logistics costs create a challenge for strategic planning. Optimize your intralogistics by introducing a digital twin to your system and achieve decisive competitive advantages.

The ideal optimization of production and logistics systems, efficient intralogistics and standardized delivery forms are central factors in the success of a business.

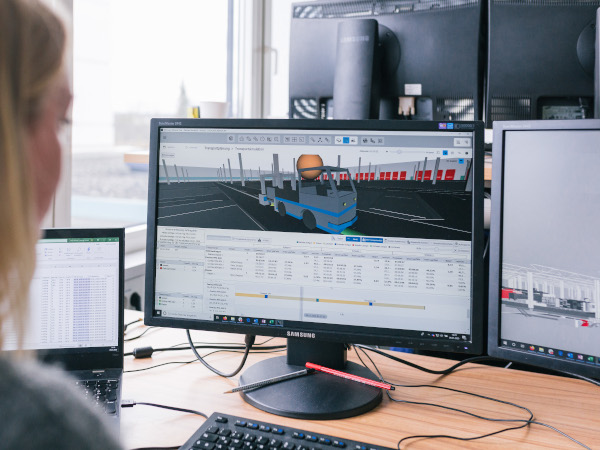

We offer a unique logistics optimization software for seamless and efficient logistics planning. ipolog is a powerful logistics planning tool for integrated and digital intralogistics solutions. ipolog uses a digital twin to assist you in the design and implementation of a more optimized logistics system. With comprehensive material flow analysis and material flow planning, you will be empowered to design your logistics systems more efficienctly than ever before.

Why is it so important to optimize your logistics planning?

Ideal logistics planning ensures that the right parts are provided at the right place, at the right time, in the right quantity and with the optimal resource requirements. It is important to be able to analyze fluctuations throughout the day and the different requirements within any given period.

Do you also face the following challenges in your logistics planning?

Planning uncertainties due to volatile markets

Individualized products need flexible logistics

Shorter cycle times and increasing cost pressure

Confusing internal processes and lack of transparency

High logistics costs and required budget cuts

Experience the added value of logistics optimization software:

Webinar

Optimize Your Logistics: From Idea to Reality in 5 Steps

Logistics optimization done right with ipolog:

See the advantages of logistics planning in ipolog at a glance:

-

From Start to Finish

ipolog software accompanies you in all phases of planning and optimizing your logistics. No matter if warehouse, picking areas, tugger trains, forklifts or driverless transport systems, everything is integrated and made transparent in one model.

-

Dynamic Calculations

ipolog software performs dynamic calculations and not calculations based on average values. Thus, a line-back simulation is carried out based on an existing production program (which is continuously changing) or logistic orders.

-

3D Visualization

3D visualization provides for better comprehension, offers a better communication basis for exchange between departments and enables planning specialists to provide competent planning solutions.

-

Structured Workflow

A predefined, structured workflow ensures better standardization within the company and also reduces your planning times.

-

Merging of Separate Departments

With ipolog, the often-separate assembly and logistics departments become one value-adding unit. The continuity between data and processes can become a reality thanks to a common digitalization tool.

-

Intuative User Interface

Many experts optimize production logistics using many different tools (Excel, Visio, PowerPoint), each of which requires training. ipolog combines different areas of expertise into one software that is easy to learn and intuitive to use.

Ipolog is not only a simulation software, but also a calculation and reporting tool. As a result, all relevant KPIs can first be calculated, then visually checked for plausibility and finally compared transparently."

Five simple steps to ideal logistics planning

1. Initial analysis of production processes including production logistics

2. Mapping the layout

3. Modeling material flows and allocation of parts

4. Calculating resource requirements

5. Evaluation of costs and personnel requirements

What can be additionally optimized with ipolog logistics software

Interested? We are happy to answer your questions!

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information