Analyze processes more easily - use materials & resources more efficiently

Fast response to data changes in planning

- Quickly simulate effects of different premises

- Automated evaluations and visualization in 2D / 3D

- Simulate and compare different staging and material flows

Plan based on detailed data and save costs

Plan material flow safely – with ipolog

The increasing complexity of production and the associated need for more flexible and faster production processes present companies with ever greater challenges in material flow planning. Effective planning requires detailed knowledge of production processes and precise planning of material and goods flows. A reasonable planning of all flows of goods is hardly possible with Excel. Too many files, too many statuses. The challenge is to be able to react quickly to changes in the product range and at the same time optimize the use of space, operating resources and personnel.

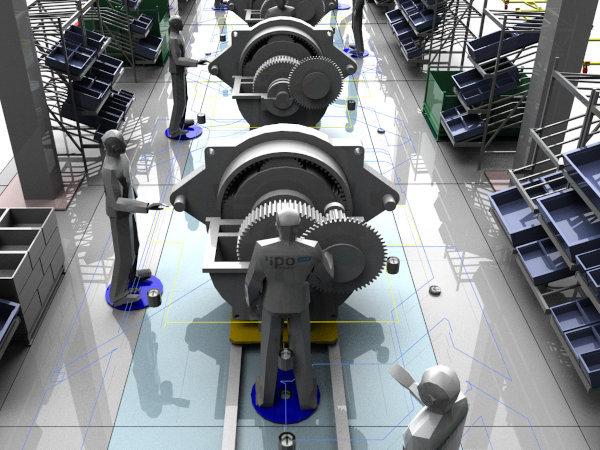

With ipolog software, you can plan your complex material flow from goods receipt to provisioning at the assembly line. Dynamic calculations and easy-to-use simulations quickly reveal potential. The results are automatically visualized in 2D or 3D. ipolog combines all necessary processes and data in one software and enables a holistic view of assembly and logistics in one system.

ipolog makes it possible to obtain a detailed and qualitative planning result with corresponding visualization in 3D already in the early phase of planning, enabling the planner to eliminate potential errors at an early stage or to already plan optimizations before implementation. This reduces unnecessary investments and avoids expensive change costs during implementation.

Benefits of Using ipolog for Material Flow Planning

Optimize material flows faster with simulation and 3D visualization

- Dynamic Heatmap

- Sankey Diagram

- 2D/3D Visualization

Simulate data changes easily

- Material flow calculations

- Standard process chain

- Transport Gantt

Plan and optimize route transports

- Layout-based transport network

- Route transports

- Dynamic trailer planning

Do you also face the following challenges?

I don't know what my material flow looks like - can't visualize it or quantify it

With ipolog software, you can create one-click Sankey diagrams as well as evaluate various material flows to accurately quantify production logistics requirements.

I find it difficult to determine the optimal route for my means of transport.

With ipolog software, you can simulate different route options based on your layout, taking into account source-sink relationships and traffic load, and find the optimum for your scenario.

I search for hours of data to create reports for management

In the ipolog software, you will find all data bundled in one tool. No annoying queries and searches. In clearly arranged evaluation modules, you have all results directly at a glance. Furthermore, ipolog enables you to simulate processes and visualize them in 3D, thus promoting a common understanding for all parties involved.

Interested? We are happy to answer your questions!