Toward a synchronized manufacturing digital twin

ipolog, SyncTwin & BMW – NVIDIA Omniverse

ipolog leading the way for BMW’s factory of the future

NVIDIA is one of the world’s most advanced developers of visual computing and AI programs. They has been leading the field for decades in terms of real-time graphics for industries such as transportation, healthcare, logistics, manufacturing, robotics and retail.

As one of the leading car manufacturers in the world, BMW is always looking to stay one step ahead. This is particularly true in the field of production management, where changing production programs and increasing individualization require innovative solutions. BMW is realizing their vision for a holistic digital twin across their global production facilities with help from the assembly and intralogistics software ipolog, simulation software from ipolog’s partner SyncTwin and the visualization platform Omniverse from NVIDIA.

Session: Toward a Synchronized Manufacturing Digital Twin

BMW uses ipolog software with the visualization from the SyncTwin Viewer to plan their production logistics in factories around the world. This exciting collaboration has been featured in the last several NVIDIA GTC conferences. See how a scattered group of planners from around the world use ipolog tools and NVIDIA Omniverse to achieve a synchronized manufacturing digital twin.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationRelevance of the cooperation for the factory of the future

Artificial intelligence and the manufacturing metaverse will just remain “buzz words” unless a platform is created on which all data can flow together and work collaboratively. BMW’s and ipolog’s approach of creating a holistic digital twin with the help of the NVIDIA Omniverse platform brings us a little closer to the future.

Effective teamwork

Production data acquisition and processing. Operational data collection takes into account all information relating to parts, assemblies, resources, routings, setup times, time recording and processes.

Simulation instead of trial & error

Holistic simulation of shared virtual worlds. Build the digital twin as an image of reality, simulate changes and then implement them.

One platform for all data

Create access to all data and link information via one platform. This can lead to a 30% faster project turnover and a 10% reduction in production costs.

ipolog Omniverse Connector

NVIDIA Omniverse is a powerful multi-GPU real-time simulation and collaboration platform. ipolog is once again leading the field of digital twin production planning by offering a bidirectional ipolog Omniverse connector. This enables a holistic digital twin of both material provision and worker simulation.

Michael Wagner, CTO of ipolog GmbH and CEO of SyncTwin GmbH, was one of the driving forces behind the fusion of Omniverse and ipolog which can be seen in the video below. He has also written several articles on the NVIDIA Omniverse which can be read here.

The ipolog Omniverse connector enables planners to share their planning scenarios in NVIDIA Omniverse, contributing to a holistic digital twin in manufacturing. Material provisioning domain semantics is supplied with ipolog element meta information.

FEATURES:

- Push ipolog Equipment Catalogs: Catalogs of racks and boxes can be pushed to the nucleus, USD templates can be used to create high fidelity visualization.

- Push and Pull ipolog Scenarios: Export ipolog 4 workspace stations and areas in the nucleus, including racks and boxgroups – metadata like material information is attached to the exported USD elements. Position changes of ipolog elements can be pulled back into the ipolog scenario, as well as new racks when created from ipolog catalog elements.

- KIT companion extensions: Install ipolog KIT extensions provided by our partner SyncTwin to display ipolog metainformation like contained materials for selected elements or import a highly detailed rack model with the item engineering tool connector extension.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

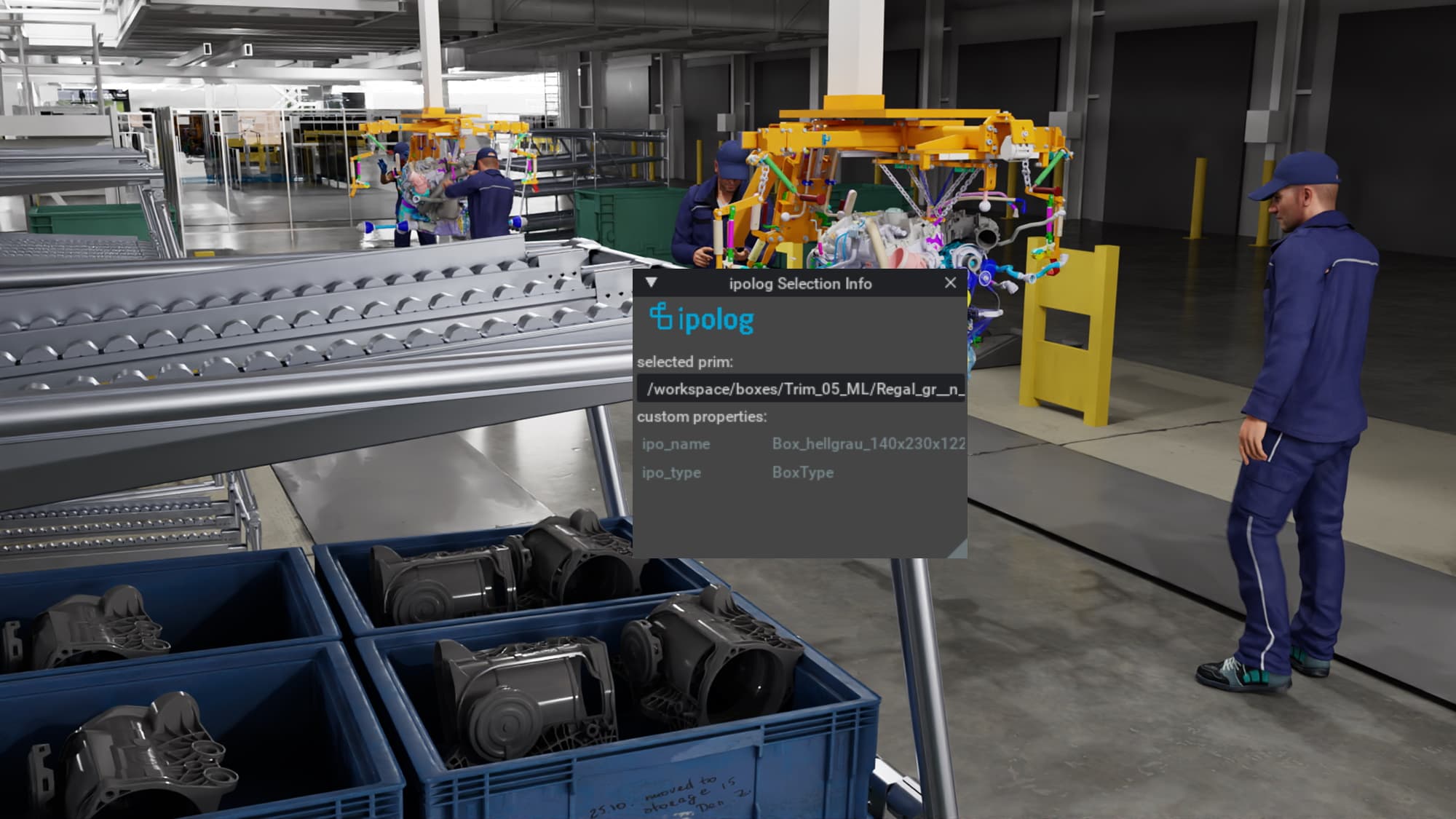

ipolog Selection Info KIT Extension

The ipolog selection info extension is a KIT extension which is able to display ipolog related meta information on selected scene elements.

FEATURES:

– Display Material Information: Display material provisioning meta information like part types on selected scene elements.

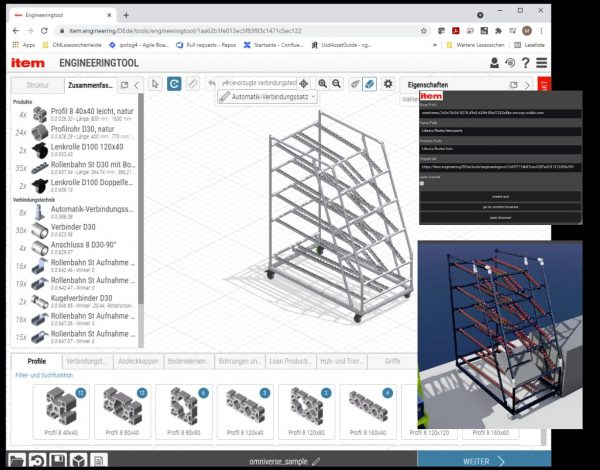

Item EngineeringTool Importer KIT Extension (powered by SyncTwin)

The item engineering tool is a web application which is provided by item GmbH to easily construct lean manufacturing equipment based on items line of aluminium profiles.

The item engineering tool importer is a KIT extension which is able to import a project created in the item engineering tool as USD component.

FEATURES:

– Import Project: Import any item engineering tool project just by providing the project url.

– Level of Details: All level of details (High, Medium & Low) provided by the item engineering tool are imported as a variant set.

SyncTwin Viewer

The SyncTwin Viewer is a digital tool with a straightforward description form that enables communication between factory planning tools. The viewer combines already existing data into a holistic digital twin that is based on the NVIDIA Omniverse. Manufacturing sites, organizations and suppliers can view and update a digital twin of the production networks – in real time! Different data sources are combined and available in the SyncTwin Viewer, which can be used with a CAD workstation or with a cloud-based solution. Realtime update of both scenarios and live data is supplied via MQTT.

NVIDIA AI Accelerated Program

ipolog is a member of the NVIDIA AI Accelerated Program to ensure performance and reliability of our AI applications that leverage the NVIDIA AI platform. We have already begun working with NVIDIA cuOpt and are impressed with the immense potential this GPU-accelerated logistics solver has for our ipolog software.

Questions about the cooperation? Send us a message!

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information