Software for assembly and logistics planning

Plan and optimize multi-variant products in ipolog

Plan and optimize complex assembly and intralogistics processes in one tool – for precise calculations and automated analyses.

Unsere Kunden optimieren bereits erfolgreich ihre Produktionsplanung mit der ipolog Software. Finden Sie heraus wie und lesen sie unsere Erfolgsgeschichten.

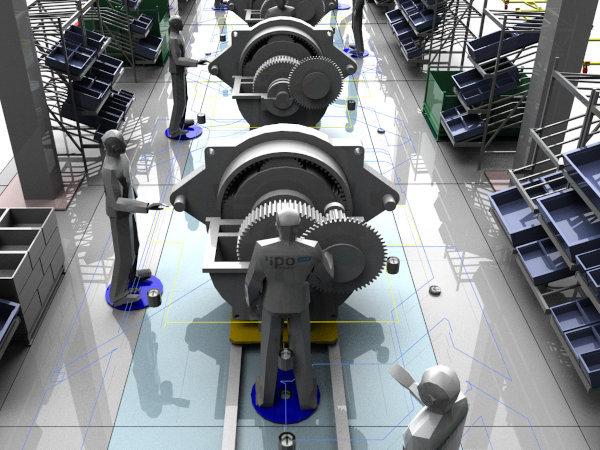

Interactive 3D visualization technology

Streamline your planning with just one click.

Efficient material and logistics planning

Consistent planning of material supply and material flow.

Evaluation and analysis functions

Make informed decisions based on your conclusions.

New functions of the ipolog software!

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWith the new Factory Viewer module in our ipolog software, you can take the visualization of your planning results in 3D to a new level!

- 3D factory view: Realistic representation of your factory.

- Comprehensive planning: Common view of all planning results.

- Transparent information in 3D: Overview of fluctuations over the course of the day and reaching or exceeding limits.

Application areas of the ipolog software

Production Planning

Discover how to create ideal production conditions for your product portfolio using quantities and variants as efficiently as possible.

Logistics Planning

Ensure that the right parts are available at the right place, at the right time, and in the right quanitity for optimized resource requirements.

Assembly Planning

Master the challenge of optimizing different workloads from cycle to cycle at a high capacity.

Material Flow Planning

Easily find and solve bottlenecks, optimize your material flow and ensure an efficient material supply.

Material Supply Planning

Take your assembly to the next level with an optimized material supply! Use ipolog to make sure that the required parts are available at the installation location in the best way possible.

Further Optimization Areas

Explore the many areas in which our ipolog software can help you reach your full potential.

Advantages at a Glance

From concept to capacity

ipolog software assists in all phases of planning and factory optimization.

Production and logistics connected

ipolog connects the often-separate assembly and logistics departments into one value-adding unit.

Expert features with intuitive usability

ipolog combines different expert areas into one software that is easy to learn and intuitive to use.

One platform for planning, visualization and simulation

ipolog combines all information into a uniform and consistent database so that everyone is on the same page.

“Digitization, visualization and data analysis were the most important decision criteria when selecting our software. So far, we have been able to achieve great improvements in provision planning with the ipolog software.”

Success Stories: What Our Customers Say

ELABO

The advantages of having a digital model of the factory are easy to see, but not always so easy to implement. There is often a lack of data, knowledge or time for 3D modelling work. ELABO was...

Kärcher Municipal

The ideal utilization of the assembly line is an important factor for success. However, the more complex the production, the more difficult this task becomes. Excel tables quickly reach their...

Logistics Planning Innovation | BMW AG

The ideal utilization of the assembly line is an important factor for success. However, the more complex the production, the more difficult this task becomes. Excel tables quickly reach their...

BMW & NVIDIA

As one of the leading car manufacturers in the world, BMW is always looking to stay one step ahead. This is particularly true in the field of production management, where changing production...

Magna Steyr Graz

The ideal utilization of assembly capacity is an important success factor. The more complex the production, the greater the challenge. Excel tables quickly reach their limits. What's more,...

You might also be interested in the following:

Plan and Compare Forklifts & AGVs Efficiently

Building direct transports efficiently and thus guaranteeing a high-frequency supply for the respective production program at optimal capacity utilization is a strong suit of the new ipolog version....

Material Flow Planning Software

The financial success of your company is heavily dependent on reliable intralogistics. Challenges quickly emerge, such as how to design material flow from the ground up or how to account for the...

Production Planning Software

A new way of thinking begins with production planning: simulate, visualize and schedule all in one software. ipolog software enables rough or detailed planning, as well as series production...

Industrial Rack Planning Software

The planning and configuration of industrial racks is an important part of material staging and warehouse planning. Individual rack planning allows for the use of limited space and reduction of...