Material Supply Planning with ipolog-Software

Organize your Material Zone with ipolog

- Schedule all containers via drag and drop

- Add changes such as new variants transparently and quickly

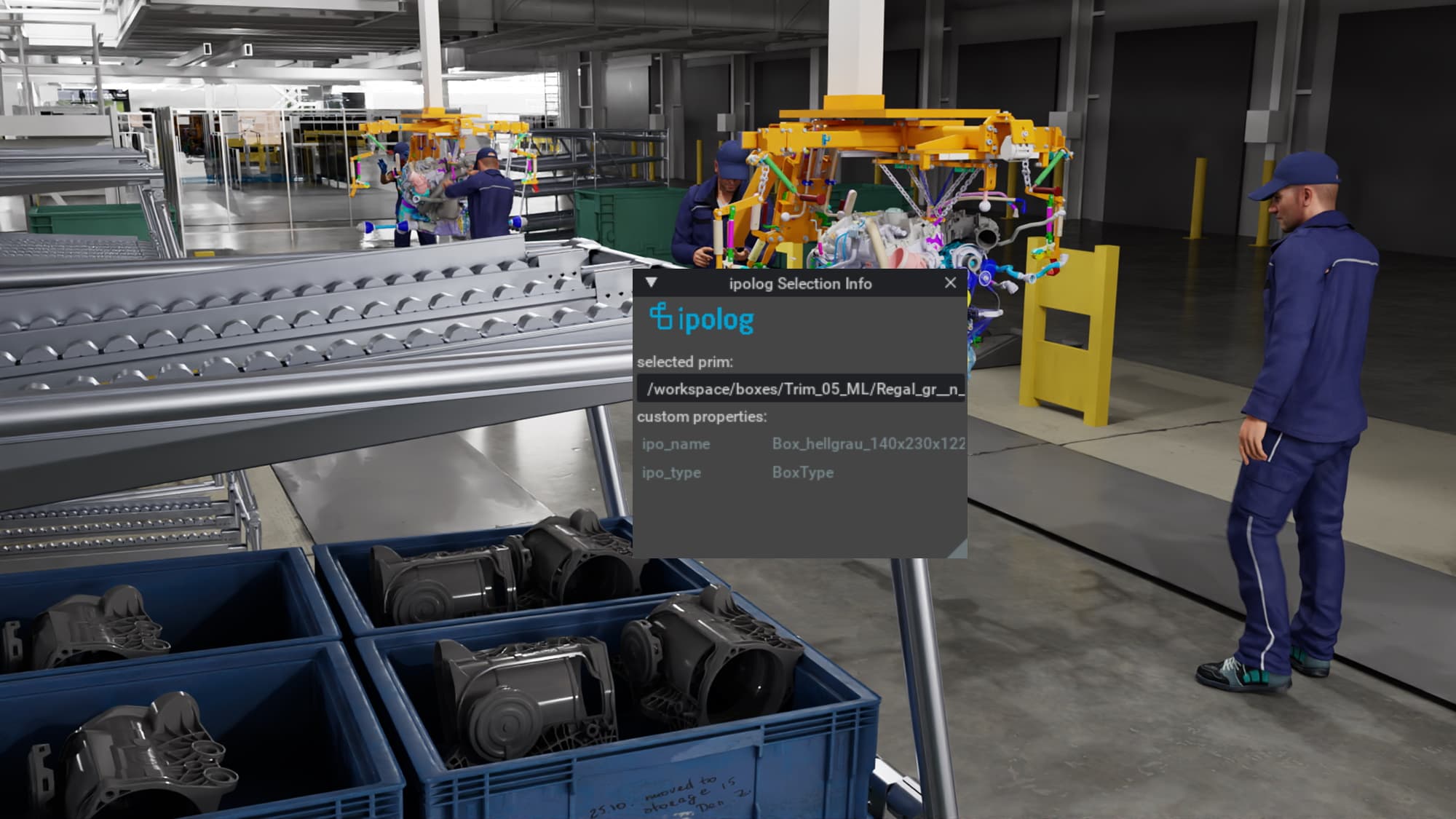

- Easy to understand planning thanks to 3D views

Avoid waste & facilitate order picking

The provision of materials in assembly and production is an increasingly important topic for many companies. The constantly expanding variety of products and product variants often leads to bottlenecks on the shop floor. Are you aware of the vast optimization potential that lies in the correct utilization of material zones?

The mission of our »ipolog planning and optimization software is to make material supply planning efficient, transparent, holistic and user-friendly!

Our ipolog software helps reduce the time required for material supply planning in production, assembly or logistics. The 3D material supply planning in ipolog ensures an ideal use of material zones and resources.

Learn more about how our software can help you succeed!

What benefits does an optimized material supply provide?

Material supply planning deals with the design and placement of containers and shelves along the assembly line, in production and in picking and storage areas. The primary objective is to provide the material in such a way that process times and route lengths are minimized while still accounting for certain conditions such as space constraints, ergonomics, type of material and delivery method.

Space Shortage

Planning Uncertainty

Large Time Expenditure

No Overview

Manual Planning

The use of software in material supply leads to these advantages

Digitalization, visualization, and the ability to analyze data were the most important decision criteria in our software selection. In the provisioning planning, we have been able to achieve significant improvements with the ipolog software so far.

This is why you should optimize your material supply with our ipolog tool!

-

Automatic Optimization

the algorithms in ipolog ensure automated processes and improvements can be achieved in a flash

-

Planning Reliability

Clear visualization for better planning reliability and easier coordination

-

Automatic Analysis

Simple scenario generation and automated evaluations

-

User-Friendly Interface

A user-friendly interface is our top priority

Think outside the box and discover further advantages of ipolog

During the installation planning process, you will know exactly what will be installed during which cycle. This allows for the material to be placed accordingly. Learn more about »assembly planning

»container and rack planning: in ipolog you can see what the resources that will be placed in the material zones look like. The exact arrangement and positioning of part numbers in the specified containers can also be seen in our user-friendly visual display. Supply concepts such as sequences, carset or product baskets can also be displayed.

To keep the distances traveled by assembly workers as short as possible, »material supply must be organized in a logical way. ipolog helps avoid non-value-adding trips to retrieve material.

Our approach for an improved material supply

1. Layout with material zones on the assembly line, in the supermarket or other storage facilities

2. Alphanumeric information about processes, required parts, containers, installation locations and material areas

3. Catalogue with 3D models of shelves, containers, products as well as environmental data or other objects (e.g. facilities)

4. Initial placement of parts with your containers

5. Detailed planning by the user

Receive improvement feedback in the software at any time