Magna Steyr Graz

Optimal Material Provisioning & Reduced Walking Distances at Graz Automotive Plant

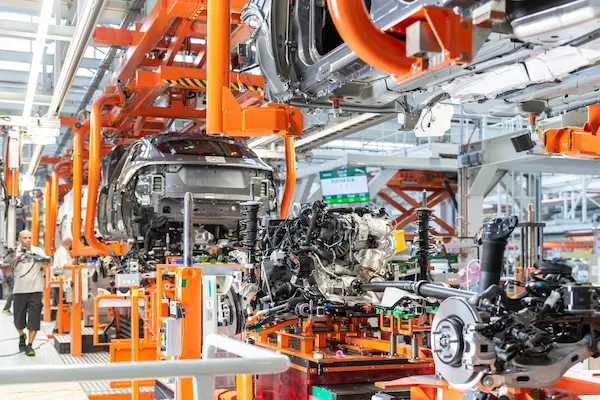

About Magna Steyr in Graz

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe ipolog software signifi cantly enhances the holistic planning of logistics and assembly at Magna in Graz, a worldwide leading brand-independent manufacturing partner for the automotive industry. With over 120 years of experience in complete cehicle manufacturing, Magna in Graz provides a comprehensive range of services from complete vehicle engineering—including systems and modules—to complete vehicle production. .

- Industry: Automotive

- Company Size: Over 10,000 employees

- Products: Complete vehicle engineering and manufacturing

- Use Case: Optimization of material provisioning and logistics

Initial Situation and Challenges at Magna

- Product Diversity and Variance: The large product diversity and high variance (models from different customers on a single production line) make planning complex and require a flexible response.

- Gaining Competitive Advantages: Competitive advantages are expected to be achieved through efficient planning of assembly and logistics processes.

- Visualization Limitations: Visualization of production lines and assembly or logistics processes is not possible with the existing planning software.

- Lack of Suitable Standard Tools: There is no suitable standard tool available that supports the complex planning tasks.

Solution

With the adoption of ipolog as a digital planning and simulation tool, material provisioning and employee walking distances are visualized, simulated, and optimized from the early stages of planning using a digital twin. This enables a more precisely timed assembly process, sequence by sequence.

Implementation at Magna

- Automated data imports into the ipolog planning software

- Simulation of assembly and logistics processes using real-time data from the master system

- Provision of planning and simulation outcomes as a comprehensive report

- Comparison of different scenarios through KPI analysis

- Real situation replicated as a digital twin: showcasing the hall, assembly line, material staging areas, material supply, and warehouse planning with walking paths in 3D

Achievements

Optimized material provisioning

Reduced employee walking distances

More efficient coordination processes

Established a perfect foundation for future logistics planning

Next Steps with Magna and ipolog

Continued enhancement of assembly and logistics planning includes:

- A unified data base for assembly and logistics

- More efficient use of resources contributing to CO2 neutrality

- Clear interfaces between departments, ensuring that assembly and logistics planners work synergistically

More information

Webinar

Brochure

Best Practice: Material Supply at Magna Steyr in Graz

More success stories

ELABO

The advantages of having a digital model of the factory are easy to see, but not always so easy to implement. There is often a lack of data, knowledge or time for 3D modelling work. ELABO was...

Kärcher Municipal

The ideal utilization of the assembly line is an important factor for success. However, the more complex the production, the more difficult this task becomes. Excel tables quickly reach their...

Logistics Planning Innovation | BMW AG

The ideal utilization of the assembly line is an important factor for success. However, the more complex the production, the more difficult this task becomes. Excel tables quickly reach their...

BMW & NVIDIA

As one of the leading car manufacturers in the world, BMW is always looking to stay one step ahead. This is particularly true in the field of production management, where changing production...

Magna Steyr Graz

The ideal utilization of assembly capacity is an important success factor. The more complex the production, the greater the challenge. Excel tables quickly reach their limits. What's more,...