Plant Expansion in Mexico

A logistics planning use case told from a planner’s perspective

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe moment that hits me

Monday morning, 7:30. I am sitting in the weekly meeting with three layout variants in PowerPoint and two screenshots from MicroStation. The assignment is a plant expansion in Mexico with a new derivative and a new assembly line. Assembly has sketched cycle times and line routing. I am supposed to set up the logistics “quickly”. Everyone looks at me as if there is a clear path. There is not, at least not on these slides.

I walk through the hall layout in my mind. Columns, fire protection axes, access roads. On the drawings these are lines and shapes. In reality they are driving lanes, crossings, buffers and interaction zones. The production supervisor says the left side is closer to incoming goods and feels better. My intralogistics colleague says the right side keeps the routes cleaner. Management asks which variant reduces transport distance, how many handling equipment we need, and how much space it costs. And I know:

Gut feeling will not get me through this. I need facts. A model that calculates, not just visualizes. I want to move from discussion to decision.

What needs to improve

I set myself three goals. Simple, Measurable, Understandable.

- Build a reliable draft layout with real dimensions within hours. No pixels, actual meters. facility layout, columns, traffic lanes, safety zones. This shows from day one what really fits in the digital planning software and what only works on slides.

- Linking logistics processes directly to the layout. Incoming goods, high rack and block storage, supermarket, sequencing, line feeding, empties loop. I need to see where material comes from, how it moves, where short waiting is possible and where queues must never occur.

- Compare variants based on KPIs instead of opinions. Space per area, route distances, number of tugger trains and forklifts, frequencies, utilization, bottlenecks. I want to say in a review that variant B saves fifteen percent distance, needs two fewer vehicles and stabilizes supply with ten percent buffer. Then it is clear why B wins.

Collaboration improves automatically. When everyone sees the same model and the same data, discussions shorten. No more assumptions. One data foundation for everyone. Management gets a common thread from goal to assumptions to scenarios to results.

My approach. Pragmatic but structured

1. Create a base layout with real dimensions

I import the facility layout and add column grids, fire protection axes and loading zones. I size the driving lanes directly. For example four point five meters for tugger trains and three point five meters for forklifts. Escape routes and safety distances are marked to avoid surprises later. The assembly layout forms the backbone with line sections, assembly stations and drop zone positions. I do not build a pretty picture. I build geometry that calculates.

2. Focus on the relevant parts set

I start deliberately small with the top one hundred parts based on volume. These represent seventy to eighty percent of the logistics effort at this stage. I group parts by load carrier type and handling. This allows me to size routes, takt times and space requirements quickly without drowning in data.

3. Derive required space for each functional area

For goods receiving, quality gate, high rack, block storage, supermarket, sequencing, empties and line feeding I define target parameters such as throughput, density, safety margins and peak factors. I use reference data from an existing plant and scale it to the new mix. The result is space corridors that must fit into the facility.

4. Place blocks, link assembly, think routes

I place functional blocks as building units. Goods receiving near the gates, supermarket near the line, sequencing close to critical stations. Then I design the material flows. Line feeding points, route hubs, one way lanes or opposing traffic, crossings, speeds. I check early where distances explode, where bundling helps or where shunting will occur. Moving a block by twenty meters is cheaper than planning extra equipment with high capital cost.

5. Create scenarios instead of copying slides

I duplicate the baseline scenario to create variants.

- A for thirty vehicles per hour

- B for fifty vehicles per hour

- C for the EV shift

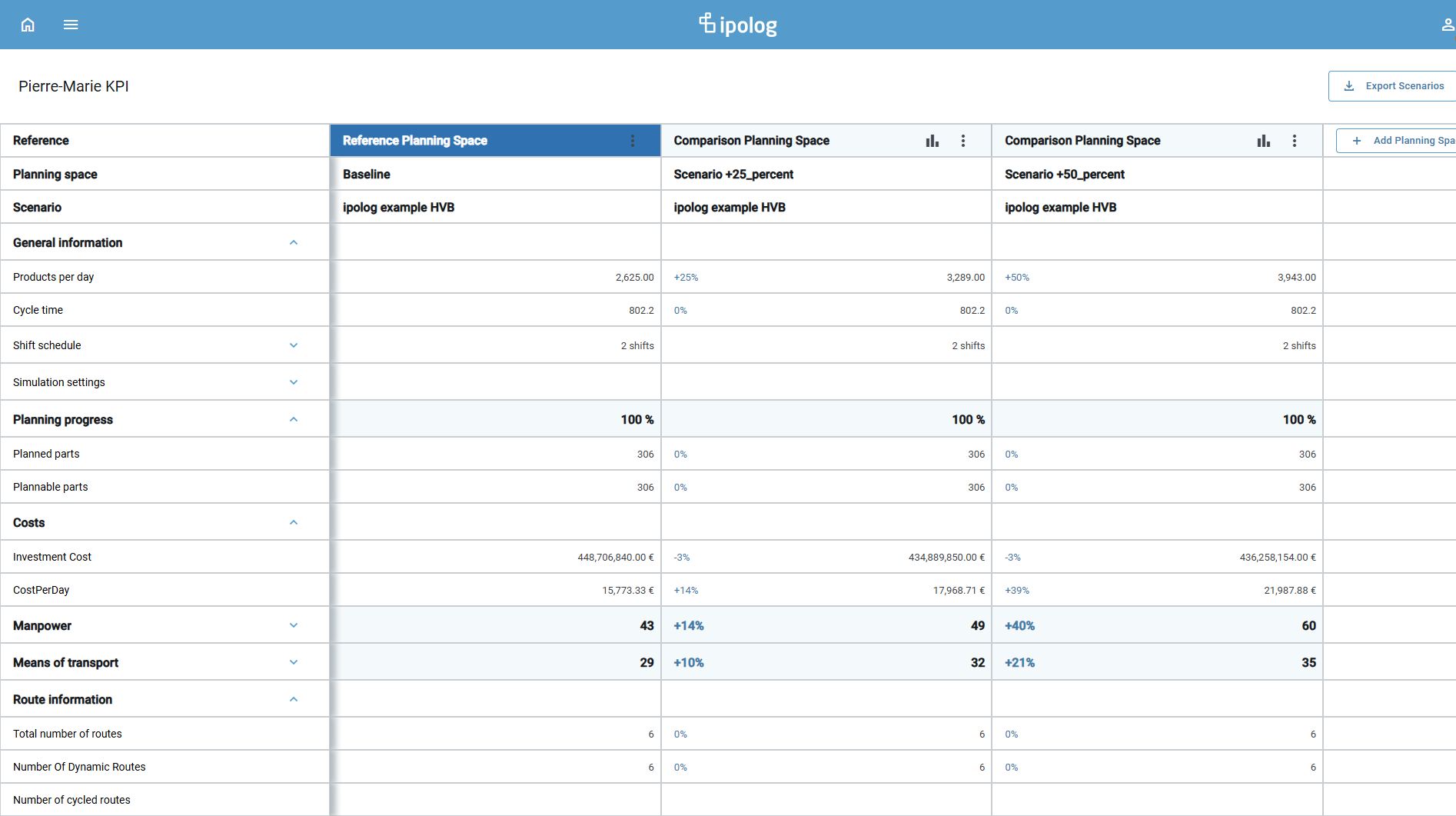

For each variant I let ipolog calculate KPIs automatically.

- Space,

- route distance,

- vehicle count,

- utilization,

- line feeding positions,

- buffer ranges and

- bottlenecks.

This turns ideas into comparable options.

6. Review with all stakeholders live in the model

Production supervisors, assembly, logistics, industrial engineering, HSE. Everyone sees the same model. A change request comes in and we move elements live. Route hub thirty meters east, supermarket reduced by one aisle, line feeding at station twelve condensed, one way logic added. KPIs update instantly. This builds trust and eliminates long email chains.

Typical obstacles and how I overcome them

Habits. We always did it this way. I counter with transparency. Heatmaps for distance, utilization and queues. Once the costs of old patterns become visible, the discussion shifts.

Incomplete data in early phases. Bills of material are not final, derivative data changes. I work with representative families and document assumptions cleanly. Weekly updates are fine because the model is built to handle them.

Combustion to EV shift in mid project. New weights, new packaging, new takt peaks. Instead of Excel marathons I update parameters and adjust space and routes. KPIs show in minutes where issues appear.

Time zones and communication. I define clear interfaces. Which KPIs do we deliver and by when. Which variant goes to management. This avoids endless back and forth.

Different definitions. Transport distance does not mean the same to everyone. I define terms such as route distance with or without empty runs and reference times. This reduces misunderstandings.

The game changer. When numbers start talking

The turning point is the moment I no longer have to guess which variant is better. I can prove it.

- How much space each area needs

- How long internal routes are per route, per day and per vehicle type

- How many vehicles are required and how they are utilized

- How cycle time changes from thirty to fifty vehicles per hour affect frequency, buffers and bottlenecks

A concrete example from our review. Variant B moves the route hub closer to the supermarket. The main route no longer crosses the line.

Result: 18% less distance, 2 fewer vehicles in peak load, 12% more buffer at critical stations. No one argues about which side feels better. The only question is whether we want to save distance or minimize space. And we decide consciously.

What really changes

Fast variant creation. In the past every idea required new slides and new Excel sheets. Today I duplicate a scenario, change two parameters, move one block or arera and have a reliable option within minutes.

Confident decisions. Management meetings focus on targets, not opinions. We say clearly whether we want to minimize distance or space, and decisions become traceable.

Change becomes manageable. Combustion to EV, new derivatives, volume changes. I update the volume model and the system recalculates. Reviews become calmer because we know what will happen instead of guessing.

Better collaboration. Everyone works with the same data. No more PowerPoint battles. One model, clear KPIs, clear actions.

Onboarding and knowledge retention. New colleagues understand the process faster because everything is visible. Layout, flows, assumptions, results. Knowledge stays in the model, not in people’s heads.

Mini case: the capacity increase from thirty to fifty vehicles per hour

Current state: Thirty vehicles per hour. Goods receiving in the north, supermarket in the center, route hub in the west. Main route with an eighteen minute cycle and twelve stops.

New requirement. Fifty vehicles per hour. Higher frequency, tight cycles, more peak load at goods receiving.

Steps:

- Adjust cycle time and recalculate frequencies

- Check critical part families

- Cluster stops

- Move the route hub forty meters closer to the supermarket

- Add one way logic

- Increase buffer positions at the line

Result: A twelve minute cycle, twenty two percent less distance, stable line supply with ten percent more buffer. One fewer tugger train and one fewer forklift due to better bundling and fewer crossings. Space shifts but becomes more efficient overall.

Learnings for the next new plant planning

- Start with the top one hundred parts: Fokus on the parts with the highest leverage and finetune later.

- No assumtions: Use measeruments and dimensions from day one

- Blocks: Place functional areas before detailing furnishings.

- Make scenarios the standard: Let the numbers speak and use KPIs to evaluate the options.

- Maintain the volume model: Changes happens daily. Better be prepared.

- Define terms and wordings from the beginning: Make sure that all speak the same language.

- Use heatmaps to visualize problems: Discuss about facts and find a solution that fits for all.

- Plan together live: Changes to be done in one model.

Conclusion

I do not plan more beautifully today. I plan more safely. I reach reliable variants faster, I see the consequences and I can justify decisions. Believing something is better shifts to knowing why one option wins.

If you are planning a new plant or derivative and still struggle with sketches and gut feeling, build a clean and simple model, link your logistics processes and let the KPIs speak.

Discussion becomes decision and planning becomes reality.

Olaf Lotze

The provision of materials in assembly and production is an increasingly important topic for many companies. The constantly expanding variety of products and product variants often leads to... »ipolog assembly planning software optimizes manual activities on the assembly line or at individual workstations by visualizing processes and »material supply directly in the factory layout. A... Das rasante Wachstum in der gesamten Logistik-Branche sowie immer stärkere Individualisierung von Produkten, Verkürzung der Lieferzeiten, hohe Verfügbarkeit und Qualität der Ware lassen auch die... A new way of thinking begins with production planning: simulate, visualize and schedule all in one software. ipolog software enables rough or detailed planning, as well as series production...Material Supply Planning Software

Assembly Planning Software

Warehouse Planning Software

Production Planning Software