Time to read: 5 min

Intralogistics (planning and optimization)

- Optimization of the internal material flow

What is intralogistics?

Intralogistics or internal logistics comprises the flow of materials, information and goods within a factory. It is differentiated from external logistics, which involves the transport of goods outside a company. Intralogistics covers all processes and areas within the factory:

- Incoming goods, outgoing goods

- Transport systems

- Warehouse (storage systems, warehouse planning, warehouse management, shelves)

- Order picking or picking zones

- Production, assembly

What is intralogistics planning?

In the context of intralogistics planning, internal processes should be optimally interconnected. All processes (material flow, storage, information flows and production processes) ideally run together perfectly.Why is it important to plan and optimize intralogistics?

Companies face many challenges. Smooth operations in intralogistics is one of them.

-

Bottlenecks

Increasing variant diversity often leads to bottlenecks in the different areas of a factory. Good intralogistics planning ensures that bottlenecks are reduced and material flows are optimized.

-

Lack of transparency

The increasing complexity of factory systems and flows of goods leads to unclear processes. A holistic integration is missing. Optimal logistics planning is now a time-consuming & complex task for the planner.

-

Time pressure

Internal processes (logistics planning) are not optimally coordinated. This results in waiting times and unnecessary breaks.

-

Rising costs

Elaborate warehouse technology, storage systems & conveyor technology lead to increasing costs.

Are you not yet planning your standard intralogistics processes? Unsure where to begin? We can help!

How are intalogistics processes planned and optimized?

The path to holistic and sustainable intralogistics is not far! Interconnected intralogistics and material flow planning can be achieved in just a few steps.

-

1. Record current status

record and bundle resources, processes, times, shift schedules, parts data, production data, Excel sheets

-

2. Layout planning

creation of a factory layout

-

3. Modeling of material flows

flow of goods is displayed

-

4. Resource requirements

The resource requirements are determined: Personnel, transport systems (driverless transport systems, tugger trains, forklifts, …), racking systems.

-

5. Cost calculations

In the last step, a cost and personnel evaluation can be determined.

In the following webinar, we will show you what intralogistics planning and optimization can look like.

Plan and optimize intralogistics: software helps!

-

Automated transportation planning

Evaluation of resource requirements and employee requirements (dynamic): tugger train requirements, employee requirements, tours per day, total distance and process times. -

Quick rescheduling

Rescheduling possible at the push of a button without having to change countless documents. -

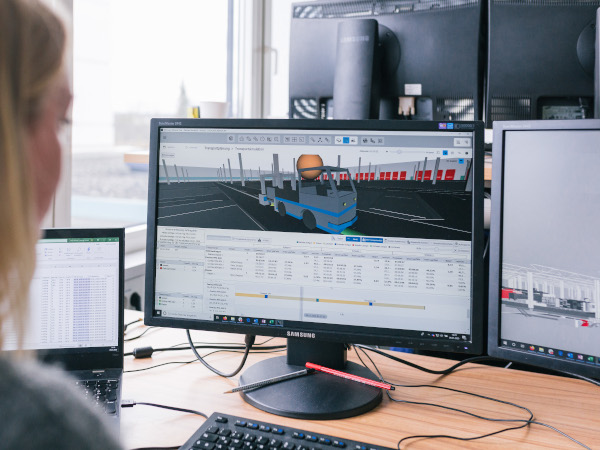

3D simulation and visualization

Visualization puts an end to unpleasant surprises because an Excel formula was copied incorrectly. A 2D representation of the material flow by e.g. Sankey diagram and heatmap also helps to optimize the material flow. -

Line back calculation

Resource planning is based on the production program. -

Automatisierte Auswertung

Evaluation of resource requirements and employee requirements (dynamic): tugger train requirements, employee requirements, tours per day, total distance and process times.

»ipolog assembly planning software optimizes manual activities on the assembly line or at individual workstations by visualizing processes and »material supply directly in the factory layout. A... Your company should actually be able to operate as efficiently as possible. Deploying your employees ideally in complex situations can be a challenge and a real Sisyphean task. The optimal... The financial success of your company is heavily dependent on reliable intralogistics. Challenges quickly emerge, such as how to design material flow from the ground up or how to account for the...Assembly Planning Software

Simply and Effectively Create a Shift Plan for Assembly with ipolog Software

Material Flow Planning Software