Software

Production Planning with ipolog software

Production planning optimization through software-supported solutions

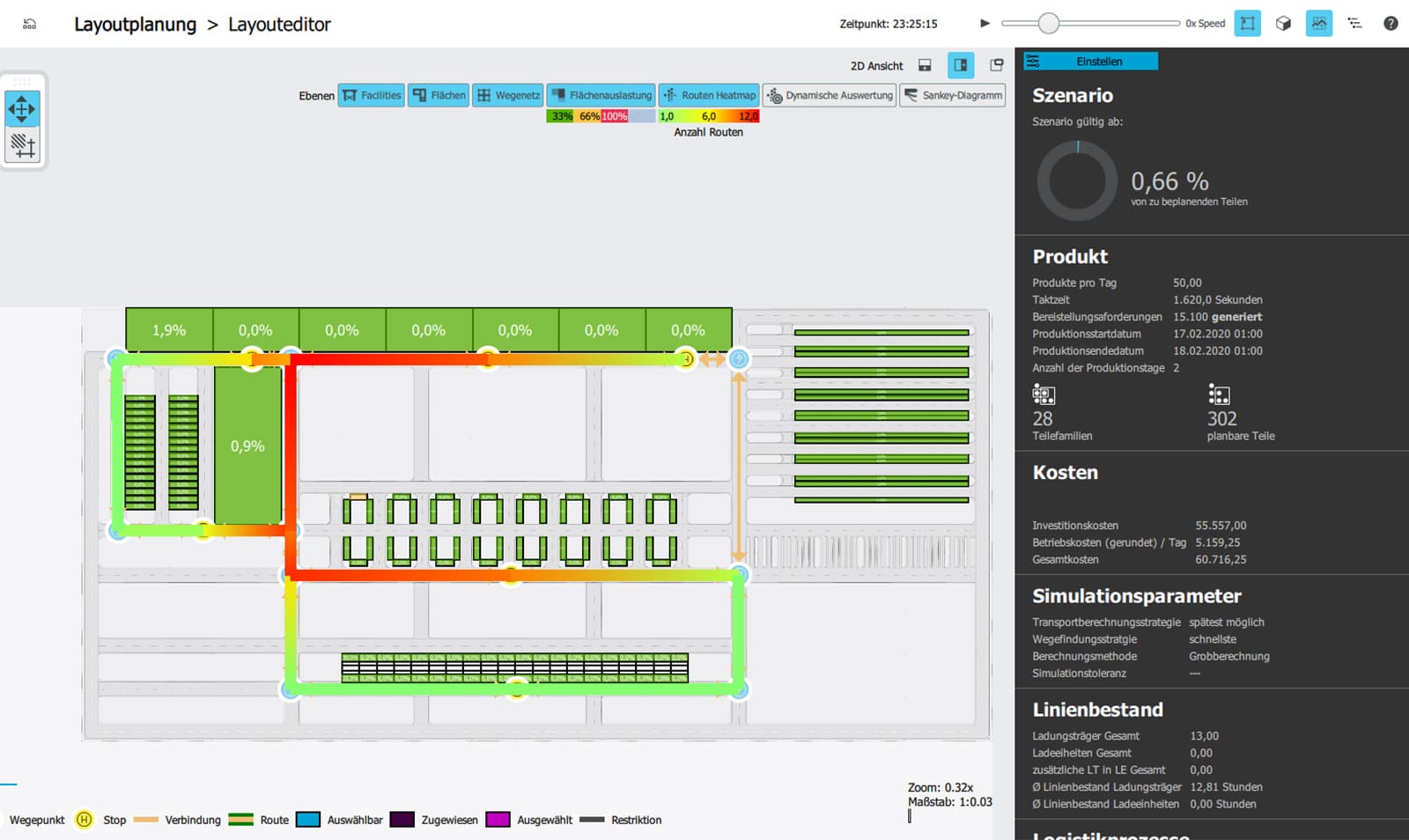

A new way of thinking begins with production planning: simulate, visualize and schedule all in one software. ipolog software enables rough or detailed planning, as well as series production planning based on a production program. Thanks to a flexible connection to other systems, material flow connections are easy to see with our integrated planning software for production & logistics. Production, assembly and intralogistics can finally be perfectly merged for collaborative planning and holistic optimization. Take the first step towards a digital factory today.

Production planning software – your key to success!

The importance of production planning in today’s factory

The basic objective of production planning is to create a production system that enables a product portfolio to produce a planned number of units as efficiently as possible. Subareas of this field include production equipment, production program and production processes.

Complex Products

Vague Forecasts

Cost Pressures & High Capital Expenditure

Advantages of production planning software

Why ipolog is the clear choice for production planning software

-

From Start to Finish

Unlike any other digital production planning system, ipolog quickly maps prepared data in a consistent model.

-

Holistic System

Production processes, production schedules, layouts, production material and internal transports are combined in a holistic digital system.

-

3D Visualization

Planned production processes are mapped directly in the 3D layout and can be checked and immediately adjusted.

Digitalization, visualization, and the ability to analyze data were the most important decision criteria in our software selection. In the provisioning planning, we have been able to achieve significant improvements with the ipolog software so far.

Your Way to Ideal Production Planning in ipolog

1. Data Preparation

2. Initial Analysis of Production Processes Including Production Logistics

3. Presentation of the Current State of Production

4. Production Optimization of All Processes

1. Preparation of the Planning Criteria

All data sources come together to create an overarching view that allows for confident planning decisions.

2. Collection of all Production-Relevant Data (processes, material, operating resources)

3. Creation of Various Planning Scenarios

4. Selection of Preferred Solution

5. Ensuring the Start of Production

Webinar

Optimize Your Logistics: From Idea to Reality in 5 Steps

Assembly Planning Webinar

Optimize Your Assembly: From Idea to Reality in 5 Steps - watch our free webinar now on-demand