So gelingt Ihnen die Lageroptimierung in wenigen einfachen Schritten

Lagerplanung mit Software erfolgreich umsetzen

Das rasante Wachstum in der gesamten Logistik-Branche sowie immer stärkere Individualisierung von Produkten, Verkürzung der Lieferzeiten, hohe Verfügbarkeit und Qualität der Ware lassen auch die Anforderungen an die Lagerplanung wachsen. Das intelligente Lager von heute muss daher auf die vielfältigen Anforderungen der Kunden ausgerichtet sein und sich flexibel auf Änderungen des Marktes einstellen.

Lagerplanung einfach gemacht – heute, morgen, immer!

Das rasante Wachstum in der gesamten Logistik-Branche sowie immer stärkere Individualisierung von Produkten, Verkürzung der Lieferzeiten, hohe Verfügbarkeit und Qualität der Ware lassen auch die Anforderungen an die Lagerplanung wachsen. Das intelligente Lager von heute muss daher auf die vielfältigen Anforderungen der Kunden ausgerichtet sein und sich flexibel auf Änderungen des Marktes einstellen.

Nutzen Sie Ihren vorhandenen Platz so effektiv wie möglich! Mit der Software ipolog liegt der Fokus auf einer maximalen Versorgungssicherheit bei minimalen Kosten.

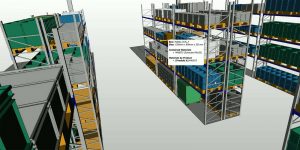

Unsere Software ipolog unterstützt Sie mit Cutting-Edge-Methoden in der digitalen Planung Ihres Lagers. Durch intelligente Algorithmen bietet ipolog Ihnen eine ideale Unterstützung zur digitalen Dimensionierung und Planung von Lagern. Durch Visualisierung wird das geplante Lager direkt im 3D-Layout sichtbar.

Erfahren Sie mehr darüber, wie Sie Ihren Platz mit unserer Software ideal nutzen können.

Warum ist eine gute Lagerplanung ein wichtiger Erfolgs-Faktor?

Haben Sie das Gefühl, dass Ihnen zu wenig Logistikfläche zur Verfügung steht? Sie haben zu wenig Platz im Lager und möchten Ihre Bestände gerne so niedrig wie möglich halten, um die Kapitalbindungskosten zu minimieren? Gleichzeitig stehen Sie vor der Herausforderung, immer diversere Produkte lagern zu müssen. Das sprengt Ihre Excel-Tabellen!

Ihre Lagerstruktur muss eine hohe Flexibilität aufweisen, um auch für nachgelagerte Bereiche die Versorgung zu gewährleisten. Bei diesen wachsenden Anforderungen an die Lagerhaltung gut aufgestellt zu sein ist nicht immer leicht.

Lagerplanung umfasst die Dimensionierung, Strukturierung und Organisation eines Lagers. Die Feinplanung eines Lagers befasst sich mit der optimalen Platzierung der darin befindlichen Waren.

Stehen Sie bei Ihrer Lagerplanung auch vor folgenden Herausforderungen?

Platzmangel im Lager

Unflexible Lagerstruktur

Große Produktvielfalt

Sie müssen auf diese Herausforderungen in der Lageroptimierung mit Automatisierung, Hightech-Lösungen und effizienter Technik begegnen. Und einer Software wie ipolog, die Ihnen Potenziale aufzeigt und mit der Sie Ihre Flächen effizient nutzen können.

Diese Vorteile bringt eine Software zur Lagerplanung

Wenn Ihre Lagerplanung in einem Programm wie ipolog erfolgt, können durch das digitale Abbild Ihres Lagers bereits im frühen Planungsstadium eine Visualisierung erfolgen sowie Engpässe und Fehler in der Planung schnell erkannt werden.

Unsere Software ipolog hilft Ihnen, Ihren vorhandenen Platz ideal zu nutzen. Durch die automatische Platzierung von Material auf Flächen und Regalen kann schnell ein reiferer Planungsstand erreicht werden.

Somit ist eine Lagerdimensionierung mit wenigen Klicks möglich. Auch Umplanungen des Lagers lassen sich schnell per Drag-and-Drop realisieren und Auswirkungen werden sofort sichtbar.

Darum sollten Sie ihr Lager mit unserer Software ipolog planen und optimieren

Früher waren Logistikzentren vorwiegend durch Paletten-Logistik für B2B-Kunden geprägt, doch zunehmender Online-Handel und die Fokussierung auf B2C hat den Komplexitätsgrad der Lagerplanung massiv erhöht. Resultierend steigt der Kostendruck und der Wettbewerb nimmt zu. Mit einer intelligenten Lageroptimierung in unserem Programm ipolog sind Sie jedoch gut für aktuelle und zukünftige Herausforderungen gerüstet.

Erleben Sie selbst die Vorteile Ihrer Lagerplanung in ipolog wie:

-

Einfacher Datenimport

Die Software ipolog verfügt über einzigartige Algorithmen, durch die Lagerflächen und Regalebenen automatisch auf Basis von einfach aufzubereitenden Daten (aus Excel, CAD, etc.) befüllt werden.

-

Schnell und einfach Szenarien vergleichen

Durch den Zusammenhang von Material und Lagerort können Szenarien und Strukturvarianten einfach ausprobiert und visuell gegenübergestellt werden.

-

3D-Visualisierung

Durch das digitale 3D-Abbild kann im frühen Planungsstadium eine Visualisierung des Lagers erfolgen und Fehler vermieden werden.

-

Schnelle Planung

Durch die einfache Aufbereitung und Modellerstellung kann die Planung sehr schnell abgeschlossen werden.

-

Alles in einem Schritt

Lagerdimensionierung und Lagerfeinplanung gelingt Ihnen in einem Schritt.

Machen Sie sich selbst ein Bild davon, wie andere Kunden bereits erfolgreich mit ipolog arbeiten.

In fünf Schritten zu Ihrer perfekten Lagerplanung:

In nur wenigen Schritten gelingt Ihnen in ipolog Ihre optimierte Lagerplanung. Nach einer Schulung der Software können Sie gleich loslegen und Verbesserungen an der Auslastung und Nutzung Ihres Lagers vornehmen. Im Detail erreichen Sie Ihre Ziele in folgenden fünf Schritten:

1. Layoutszenarien aufbauen

2. Daten aufbereiten

3. Lagerart definieren

4. Konzept auswählen

Entscheiden Sie sich für eine chaotische Lagerhaltung oder eine Festplatz-Zuordnung Ihrer Materialen und arbeiten Sie damit in ipolog weiter.

5. Feinplanung

Darüber hinaus haben Sie in unserer Software ipolog die Möglichkeit, innerhalb eines Taktes zusammenhängende Arbeitspakete variabel zu verschieben oder einen bzw. mehrere Arbeitsplätze pro Takt zu belegen.

Möchten Sie gleich mit der Optimierung Ihrer Personaleinsatzplanung beginnen? Dann starten Sie mit uns durch! Gerne besprechen wir Ihre Anforderungen persönlich.

Digitalization, visualization, and the ability to analyze data were the most important decision criteria in our software selection. In the provisioning planning, we have been able to achieve significant improvements with the ipolog software so far.