Time to read: 7 min

Intralogistics Optimization

- Improve internal logistics processes with ipolog intralogistics software. For effective intralogistics solutions.

Digital intralogistics planning – take your intralogistics to the next level!

Would you like to optimize your value chain now without waiting for the future? Then you’ve come to the right place! By digitalizing your logistics processes, you can link operational departments and create transparency from incoming to outgoing goods. These are the optimal basic requirements for efficient logistics planning and the basis for smooth intralogistics.

Our »ipolog logistics software supports you on your path to digitalization. With the help of our software and experts, we can increase and improve the performance of your intralogistics – step by step. ipolog is a powerful tool that enables you to design and evaluate your intralogistics systems both optimally and efficiently. Achieve transparency in your intralogistics processes, improve your capacity utilization and guarantee a smooth material flow. Invest in a digital intralogistics solution now.

Digitalized intralogistics planning as a solution to your challenges

In intralogistics planning, solutions are generated in the environment of internal logistics in a systematic process and under consideration of objective goals. General tasks are the planning of logistics processes and material flow, investment planning, forecasting of costs and product influence in line with production.

Do you also face the following challenges when optimizing your internal logistics?

-

Volatile markets lead to inaccurate forecasts

Fluctuating markets make reliable forecasting almost impossible. To counteract this, you must be able to dynamically adjust your intralogistics planning at any time, from delivery and picking to material transport and final assembly. Manually impossible! ipolog enables you to adjust your material flow planning at the push of a button in order to react quickly to fluctuations.

-

Individualized products need flexible processes

The trend continues to move towards batch size 1. This development unfortunately creates a lot of disruption in internal business processes: picking is becoming more complex, warehouse logistics are becoming confusing, and goods transport is becoming inefficient due to the increasing number of small goods containers. Logistics processes that are no longer manageable mean that bottlenecks persist and optimization potential remains unused. Digital intralogistics planning helps you create transparency and maintain an overview. Our ipolog intralogistics software helps you easliy and quickly plan the required resource depending on the production program and can specifically optimize the lead time.

-

Cost & time pressure

Cost & time pressure

Are shorter planning cycles, increasingly complex products and rising cost pressures keeping you up at night? Are your key figures plummeting? Are you always one step behind with process optimization? No wonder, because these challenges can’t be mastered with the usual tools. Digitalizing your logistics processes helps you create transparency about transport costs, gain an overview of internal key fgures and uncover and fix bottlenecks. Become the master of your internal material flow with digital support from ipolog!

-

Unclear internal processes and lack of transparency

Are there too many cooks in the kitchen? Do countless documents have to be modified and many specialists from different departs have to sign off on logistics planning? This takes lots of extra time and is often confusing for collegues from other departments. Would you like to make things easier and create more transparency across departmental boundaries? This can only be accomplished with digitalized intralogistics. The seamless integration of all information in ipolog creates transparency and enables productive team work with a sustainable improvement of processes.

Discover the potential that lies in intralogistics software solutions

With the integration of all data in one tool, enjoy a platform on which all specialists can productively work together. Warehouse logistics, flow of goods and automatic guides vehicles are no longer planned in indivudal documents and workflows, but holistically in one software. Master the multitude of documents, bundle all information in one place and create a unified concept of your supply chain. The understanding of the big picture of your internal logistics processes will increase potential across the entire supply chain. Begin the optimization of your supply chain now and shorten the „time-to-market“.

These are the advantages of process optimization in ipolog

Our ipolog intralogistics software offers you a wide range of functions and thus supports (almost) all areas of logistics planning. From »tugger train planning to »warehouse planning, the entire logistics process is put under the microscope. No other tool on the market offers an all-encompassing range of functions like ipolog. Furthermore, ipolog offers a simple and intuitive user interface and a structured workflow, providing an overview in the planning process.

Here you can see an overview of the advantages of digitalized logistics optimization:

-

All processes at a glance

Process optimization only works if you can holistically evaluate supply chains, warehouse, delivery and worker processes. ipolog software helps you systematically plan your logistics processes, integrating all areas and simulating and visualizing the interfaces.

-

Dynamic values instead of average values

ipolog software dynamically calculates the flow of goods and not on the basis of average values. Line-back requirements and processes are defined starting from the production program and a process analysis is performed.

-

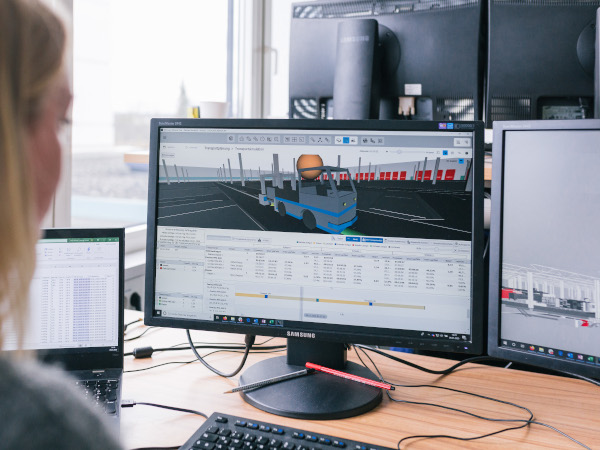

3D visualization

In ipolog, we create the digital twin of your logistics processes. Your processes can then be visualized and clearly presented for everyone in 3D. This visualization allows for a quick analysis of critical interfaces, poor processes and unintended changes and to eliminate any disadvantages.

-

Once you have integrated all data into ipolog, you can compare and assess different scenarios and make adjustments to your processes and resources at the push of a button. No more adjustments in countless documents. Quickly and safely test different ideas and compare their effects. Improve your planning times now.

-

One value added unit instead of analysis and optimization of sub-processes. Consistency and transparency in your intralogistics planning finally becomes reality through a common digitalization tool – everyone’s finally on the same team!

-

Easy and intuative operation

Put an end to the multitude of tools! Experts work together in one tool to optimize your intralogistics.

-

Automated guided vehicles, tugger trains, forklifts: finally an end to empty runs

A dynamic line-back calculation reveals the time windows in which means of transport are poorly and inefficiently deployed. Digitalization in ipolog enables the coordinated use of your means of transport. Leverage your potential now!

-

Space and efficiency in the warehouse

Space is money! Warehouse logistics are methodically planned with ipolog. Picking that is coordinated with the order situation enables efficient use of valuable warehouse space. The allocation of racks can be optimized through rack planning. This means that you will always have enough space for new deliveries. Merge incoming goods and warehouse into one unit!

Digitalizing your logistics processes – in just five steps:

-

1. First analysis and preparation of the planning fundamentals

Determine and integrate data (resources, process and time modules, shift schedule, parts data, production data, Excel spreadsheets)

-

2. Visualization of the layout

With your layout, we lay the foundation for planning all areas: From warehouse to production.

-

3. Modeling of material flows and allocation of parts

Mapping of logistics processes as a digital twin. This allows your intralogistics to be optimized on the basis of a digital reality.

-

4. Calculate resource requirements

The daily resource requirements of your intralogistics are determined with information on workloads, AGVs, tugger trains and forklifts integrated into the software.

-

5. Evaluate costs and worker assignment

Calculate and reduce costs of workers and means of transport automatically. All key figures at a glance.

Contact us for a complimentary consultation! We would love to show how ipolog can make a difference in your factory!

But that’s not all…ipolog can do even more!

We partner with various logistics service providers, logistics consultants and planning offices. This allows us to offer logistics optimization in ipolog accompanied by an expert we trust. Within the scope of a logistics consultation, a process analysis in ipolog discovers potential that has not yet been utilized. All-around support for an improved value chain.

Die Basis für einen reibungslosen Produktionsprozess ist das Vorhandensein aller notwendigen Kapazitäten. Fehlen benötigte Sachressourcen und Personalressourcen, stockt die Fertigung. Gerade bei... In many manufacturing companies, final assembly is the stage in the production chain where the greatest value is created for the product. Even the best assemblies and vendor parts are of little... The financial success of your company is heavily dependent on reliable intralogistics. Challenges quickly emerge, such as how to design material flow from the ground up or how to account for the...Resource Planning Software

Simulation Software for Material Flow

Material Flow Planning Software